1 Introduction

The transfer window is used as an auxiliary device for the clean room, mainly for the transfer of small items between the clean area and the clean area, the non-clean area and the clean area, to reduce the number of clean rooms to open the door, to minimize the clean area Pollution. Transfer window is widely used in micro-technology, biological laboratories, pharmaceutical plants, hospitals, food processing industry, LCD, electronics factory, and so all need air purification sites. Transfer window made of stainless steel plate, smooth and smooth. Two-door interlocking, effectively prevent cross-contamination, with electronic or mechanical chain device, and configure the UV germicidal lamp.

2 classification

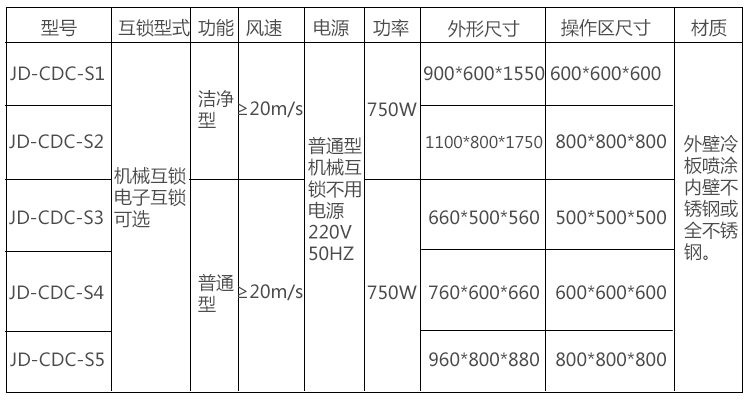

Transfer window is divided into three categories: 1, electronic chain transfer window 2, mechanical chain transfer window

Transfer window by working principle can be divided into the wind transfer window and the general transfer window, laminar flow transfer window. Can be made according to the actual requirements of various models of transmission window.

Optional accessories: walkie-talkie, germicidal lamps and other related functional accessories.

3 Features

⒈ short distance transfer window work surface with stainless steel plate, smooth and smooth wear

⒉ long distance transfer window work table with no power roller, easy to transfer items easy

⒊ both sides of the door with a mechanical interlock or electronic interlock, electronic latch device to ensure that both sides of the door can not be at the same time open. Transfer window

4, according to customer needs, customized non-standard size and floor-style transfer window.

⒌ wind mouth outlet wind speed up to 20s or more.

⒍ using a high efficiency filter, filter efficiency: 99.99%, to ensure that the purification level.

⒎ use EVA sealing material, high sealing performance.

⒏ can match paired walkie-talkie

4 working principle

⒈ mechanical interlock device: the internal form of mechanical use to achieve interlock, when a door open, the other door can not open, you must turn off the other door and then open another door.

⒉ electronic interlock device: the internal use of integrated circuits, electromagnetic locks, control panels, lights and other interlock, when one of the doors open, the other door open light does not light, told the door can not open, while electromagnetic Lock action to achieve interlock. When the door is closed, the other solenoid starts to work and the indicator lights up, indicating that the other door can be opened.

5. Use method

The transfer window is managed by the cleanliness level of the higher-level clean area connected to it. For example, the transfer window between the code room and the filling should be managed according to the requirements of filling. After get off work by the clean area operator is responsible for the transfer of the internal surface of the window wipe clean, and open the UV sterilization lamp for 30 minutes.

1 material into the clean area, must be strictly separated from the flow channel, from the production workshop material dedicated channel access.

2 materials into the raw materials from the preparation process by the person in charge of the organization of personnel off the package or the appearance of cleaning treatment, the transfer window to the workshop raw materials temporary room; within the package in the temporary storage of their packaging, the Transfer the window into the private room. Workshop synthesis and preparation, the main packaging process for the material transfer.

3 through the transfer window delivery, you must strictly implement the transfer window inside and outside the door "open one" requirement, two can not open at the same time. Open the door before the material into the door before closing, and then open the door to the material out, closed, so the cycle.

4 in the clean area of the material sent, the material should be transported to the relevant material in the middle of the station, according to the material into the reverse of the program out of the clean area.

5 all semi-finished products shipped from the clean area, are required to send from the transfer window to the temporary storage, the logistics channel transported to the packaging room.

6 Easily polluted materials and wastes shall be transported from their dedicated transfer windows to non-clean areas.

7 after the end of the material, should be promptly clean up the clear room or intermediate station scene and transfer window health, close the transfer window inside and outside the channel door, do a good job cleaning and disinfection work.